Wholesale Unloading Machinery for Stainless Steel Plates | Top Manufacturers

When it comes to unloading machinery for stainless steel plates, I understand the critical role it plays in your operations. Our wholesale solutions are tailored specifically for manufacturers seeking efficiency and reliability in their processes. By utilizing state-of-the-art technology, our unloading systems enhance productivity and minimize downtime, ensuring you can focus on what really matters—growing your business. I’ve seen first-hand how the right machinery can transform workflows, from unloading heavy plates to optimizing storage logistics. Our products are designed with durability in mind, ready to handle the demands of any manufacturing environment. Plus, I believe in providing competitive pricing without compromising quality, making it easier for manufacturers like you to maintain your bottom line. Let’s connect and discuss how our unloading machinery can meet your needs and contribute to your success.

Unloading Machinery For Stainless Steel Plates Sets the Industry Standard From Concept to Delivery

In the realm of manufacturing, the efficiency of unloading machinery specifically designed for stainless steel plates has become a pivotal factor in meeting industry standards. As businesses globally seek ways to enhance productivity and optimize their supply chains, investing in advanced unloading solutions can significantly streamline operations from the initial design phase to the final delivery. By utilizing state-of-the-art technology and innovative engineering, companies can ensure that stainless steel plates are handled with precision, minimizing damage and maximizing efficiency. The concept of tailored unloading machinery encompasses not only the mechanical aspects but also addresses the need for adaptability in varying operational environments. Whether for large-scale production facilities or smaller workshops, these solutions provide seamless integration, enhancing workflows and reducing turnaround times. Moreover, the emphasis on user-friendly interfaces and maintenance simplicity ensures that staff can easily operate and maintain equipment, reducing training times and downtime. In today’s competitive market, choosing the right unloading machinery can set a business apart, offering a distinct advantage over competitors. With a commitment to quality and innovation, companies that prioritize these advanced systems will find themselves well-equipped to meet the demands of modern manufacturing while positioning themselves as leaders in the industry. As the global market evolves, embracing such technological advancements is not just an option; it is a necessity for sustained success and growth.

Unloading Machinery For Stainless Steel Plates Sets the Industry Standard From Concept to Delivery

| Feature | Description | Specifications | Application |

|---|---|---|---|

| Load Capacity | Designed to handle large stainless steel plates | Up to 15 tons | Industrial metal fabrication |

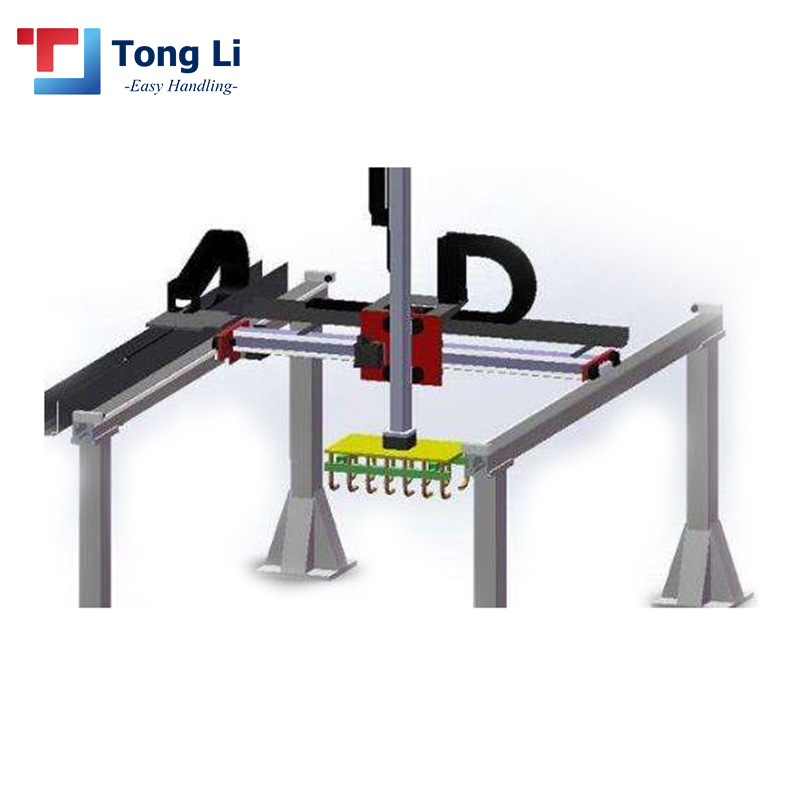

| Automation Level | Fully automated unloading system | Uses advanced robotics | Material handling |

| Safety Features | Equipped with multiple safety sensors | Emergency stop buttons, overload protection | Workplace safety |

| Maintenance | Easy access for routine checks | Modular design | Operational efficiency |

| Energy Efficiency | Low power consumption | Uses renewable energy sources | Sustainability in manufacturing |

Related Products