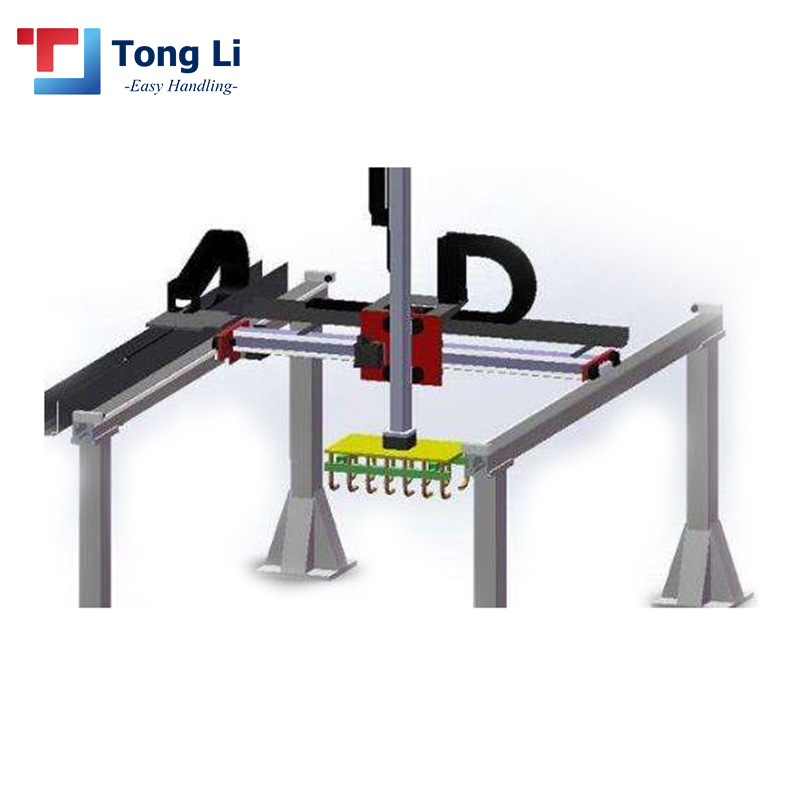

Top China Manufacturer of Loading And Unloading Manipulators for Efficiency

When I think about enhancing efficiency in material handling, the Loading And Unloading Manipulator really stands out. Whether you're operating in a busy warehouse or a manufacturing plant, this innovative solution streamlines the unloading and loading processes, reducing both time and labor costs. As a product sourced from a reputable manufacturer in China, it combines durability with high-performance capability. What I appreciate the most is how easy it is to adapt to various workloads. The manipulator's smart design allows for effortless handling, minimizing the risk of injury and maximizing productivity. It’s an investment that pays off quickly, making it essential for businesses looking to optimize their operations. If you're considering ways to enhance your workflow and improve safety, I truly believe this manipulator could be the game-changer you need. Let's take your loading and unloading tasks to the next level!

Loading And Unloading Manipulator Application Trusted by Pros

In today's fast-paced manufacturing landscape, efficiency and reliability are paramount. Loading and unloading manipulators have emerged as essential tools that streamline operations, enhance productivity, and minimize human error. These advanced systems are designed to handle a variety of materials and products, enabling businesses to optimize their logistical processes. Companies across various industries are increasingly turning to these manipulators to improve not just their operational efficiency, but also the safety of their workforce. Advanced loading and unloading systems not only reduce the labor involved in moving heavy items but also integrate seamlessly with existing production lines. Many of these manipulators are equipped with smart technology that provides real-time data and analytics, allowing businesses to make informed decisions. This capability is particularly valuable for global buyers seeking to enhance their inventory management and reduce operational costs. As purchasing decisions are made with an eye on sustainability and eco-friendliness, the energy-efficient designs of these manipulators offer an attractive advantage. Choosing the right loading and unloading manipulator is crucial for maximizing return on investment. Buyers should consider factors such as versatility, ease of maintenance, and the ability to customize solutions based on specific operational needs. By investing in reliable and high-quality manipulators, manufacturers can expect significant improvements in their supply chain efficiency, ultimately leading to increased profitability and enhanced customer satisfaction. As global demand for innovative handling solutions continues to grow, businesses that embrace this technology will be well-positioned to thrive in a competitive marketplace.

Loading And Unloading Manipulator Application Trusted by Pros

| Application Name | Industry | Manipulator Type | Max Load (kg) | Precision (mm) | Application Area |

|---|---|---|---|---|---|

| HeavyDuty Arm | Manufacturing | Articulated | 500 | 0.1 | Assembly Line |

| SmartLoader | Logistics | SCARA | 300 | 0.5 | Package Handling |

| QuickPick | Retail | Delta | 200 | 0.3 | Order Fulfillment |

| FlexiLift | Construction | Telescopic | 750 | 1.0 | Material Handling |

Related Products