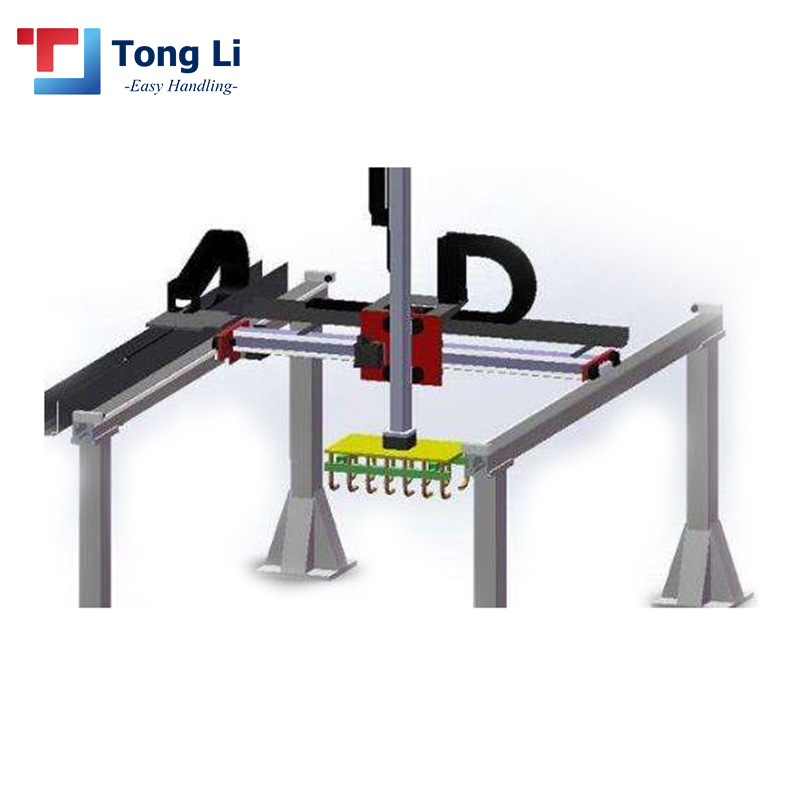

High-Quality Production Line Palletizing Robot Supplier for Optimal Efficiency

When it comes to optimizing your production efficiency, nothing beats a high-quality production line palletizing robot. With a reliable supplier like us, you can trust that our robotic solutions will streamline your operations. I've seen firsthand how these robots can reduce labor costs and increase throughput. Our palletizing robots are designed for flexibility, handling diverse products with precision, making them perfect for any production line. I know how vital it is to have machinery that not just meets but exceeds your expectations. That's why we focus on quality and durability, ensuring our robots stand the test of time. Investing in a production line palletizing robot means investing in the future of your business. Let me help you elevate your operations—you won't regret partnering with a supplier dedicated to your success. Reach out today to learn more about how we can meet your unique needs!

Production Line Palletizing Robot Application More Than a Supplier - A Partner

In today's competitive manufacturing landscape, companies are no longer looking for mere suppliers; they seek reliable partners who contribute significantly to their operational efficiency and growth. The application of palletizing robots in production lines represents a transformative shift that goes beyond automation—these sophisticated systems are becoming integral partners in enhancing productivity and reducing costs. By implementing advanced palletizing solutions, businesses can streamline their processes, improve accuracy, and address labor shortages. These robots adeptly handle complex tasks, ensuring consistent performance and adaptability across various products and packaging formats. This partnership empowers manufacturers to focus on innovation and quality while achieving faster turnaround times and meeting the demands of a dynamic marketplace. Moreover, an effective collaboration extends to continuous support and innovation. Understanding the unique challenges faced by manufacturers allows for tailored solutions that evolve alongside the business. A true partner invests in training, integration, and ongoing maintenance, ensuring that companies maximize their investment and realize the full benefits of automation. Embracing this partnership model not only enhances productivity but also fosters long-term success in an ever-changing industrial environment.

Production Line Palletizing Robot Application More Than a Supplier - A Partner

| Application Area | Robot Type | Payload Capacity (kg) | Speed (pallets/hour) | Integration Complexity | Benefits |

|---|---|---|---|---|---|

| Food & Beverage | Delta Robot | 5 | 800 | Low | High speed and precision |

| Consumer Goods | Articulated Robot | 20 | 600 | Medium | Flexible handling of various products |

| Automotive | SCARA Robot | 15 | 400 | High | Precision and consistent output |

| Electronics | Collaborative Robot | 10 | 500 | Low | Enhanced worker safety and efficiency |

Related Products