Wholesale Lifting Robot Manufacturers: Quality Solutions for Your Needs

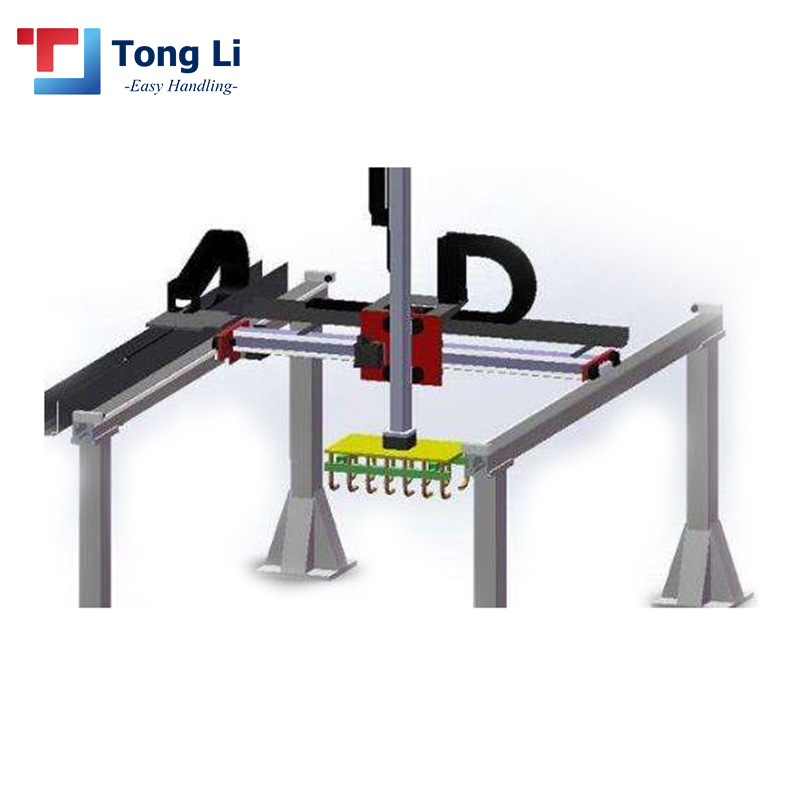

With our advanced Lifting Robot, I can truly say that we are revolutionizing warehouse operations. If you're in the wholesale space or a manufacturer, you'll appreciate how this innovative solution can streamline your lifting and transporting needs. Designed to maximize efficiency, this robot handles heavy loads with ease, reducing the risk of workplace injuries and improving productivity. I've seen firsthand how it transforms labor-intensive tasks into simple, automated operations. Whether it's moving pallets or stacking items, our Lifting Robot adapts to various environments, making it an ideal choice for any B2B purchaser. Plus, its user-friendly interface ensures that training your staff is a breeze. Investing in this technology means not just saving on labor costs, but also boosting your operational efficiency. No more misplaced items or wasted time – with our Lifting Robot, your manufacturing process can run smoothly. Reach out today to learn more about bulk purchasing and how we can support your business needs!

Lifting Robot Supplier For the Current Year

In today's rapidly evolving industrial landscape, the demand for lifting solutions is increasingly crucial. As businesses strive for efficiency and safety in their operations, the emergence of advanced lifting robots has transformed the way goods are handled. These innovative machines not only enhance productivity but also reduce the risk of workplace injuries, ensuring a safer environment for employees. For global purchasers seeking reliable lifting robot suppliers, understanding the latest technologies and market trends is essential to making informed decisions. Lifting robots today are equipped with cutting-edge features such as artificial intelligence, adaptive learning capabilities, and superior payload management. This evolution allows them to perform complex tasks with precision and flexibility, catering to various sectors from manufacturing to logistics. As automation continues to be a key driver for businesses looking to optimize their supply chains, investing in high-quality lifting robots can yield significant long-term benefits, including cost savings and improved operational efficiency. When sourcing lifting robot suppliers, it is imperative to assess their experience, product range, and customer support services. Establishing a partnership with a supplier who understands the specific needs of your industry can lead to tailored solutions that maximize efficiency. As you evaluate potential suppliers, focus on their ability to provide not only robust lifting systems but also comprehensive training and after-sales support to ensure seamless integration into your operations.

Lifting Robot Supplier For the Current Year

| Supplier Name | Country | Robot Type | Payload Capacity (kg) | Application Area |

|---|---|---|---|---|

| Supplier A | USA | Articulated Robot | 100 | Manufacturing |

| Supplier B | Germany | SCARA Robot | 50 | Electronics |

| Supplier C | Japan | Collaborative Robot | 25 | Assembly |

| Supplier D | China | Mobile Robot | 200 | Logistics |

| Supplier E | South Korea | Delta Robot | 15 | Food Industry |

Related Products