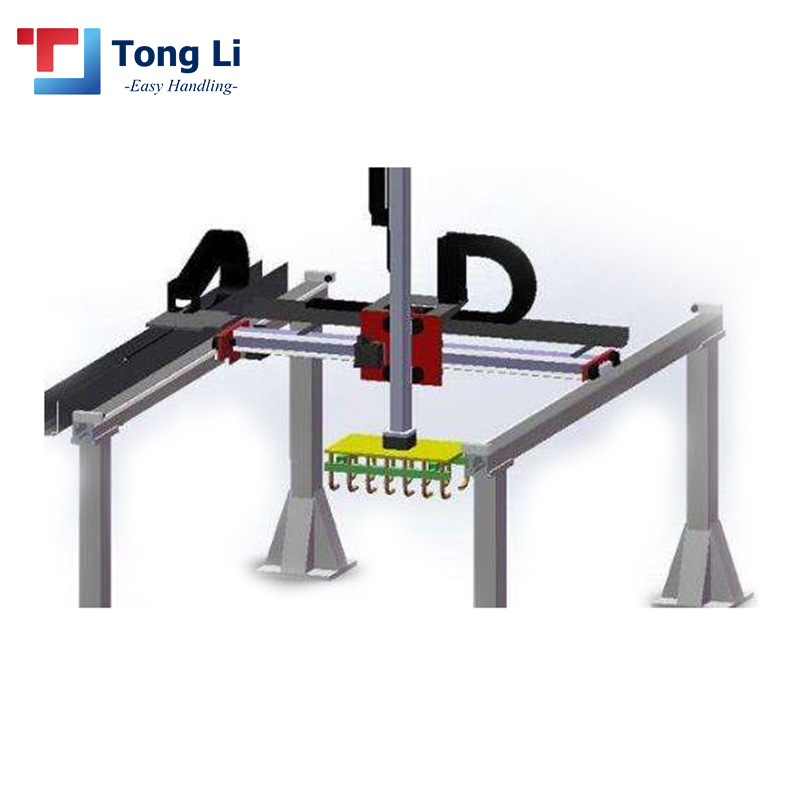

High-Quality Palletizing System from Trusted Supplier for Your Needs

As a business owner in the logistics sector, I know how crucial it is to streamline operations and improve efficiency. That’s why I want to share my thoughts on our high-quality palletizing system, a game-changer for warehouses and production lines. This system not only enhances productivity but also ensures that your products are packaged securely and efficiently. With years of experience, I’ve partnered with a reliable supplier that understands the nuances of industrial needs. Our palletizing solution is versatile, accommodating various package sizes and weights, ultimately reducing labor costs and minimizing errors. I’ve seen firsthand how implementing this system can transform workflows and elevate overall performance. If you’re serious about optimizing your operations, investing in a high-quality palletizing system could be your next best move. Let’s discuss how this solution can fit into your business strategy today!

Palletizing System Stands Out Pioneers in the Field

In the ever-evolving landscape of industrial automation, palletizing systems have emerged as crucial components for enhancing operational efficiency and optimizing supply chains. This is particularly true for businesses looking to streamline their operations while maintaining high standards of quality and reliability. With advancements in technology, modern palletizing systems are designed to adapt seamlessly to various industry demands, ensuring that products are handled with precision and care. What sets leading palletizing systems apart is their ability to integrate cutting-edge features such as AI-driven robotics and advanced sensors, allowing for real-time monitoring and sophisticated decision-making processes. This not only reduces labor costs but also minimizes the risk of errors, enhancing overall productivity. As global suppliers continue to seek innovative solutions, investing in state-of-the-art palletizing technology can yield significant returns through improved throughput and reduced downtime. Moreover, sustainability is becoming increasingly important in procurement decisions. Modern palletizing systems are engineered with energy-efficient components and designs that support eco-friendly practices. By choosing systems that prioritize sustainability, businesses not only comply with regulatory standards but also position themselves favorably in the eyes of environmentally conscious consumers. As the demand for efficient, flexible, and sustainable solutions grows, companies that embrace advanced palletizing technology will undoubtedly stand out as pioneers in their field.

Palletizing System Stands Out Pioneers in the Field

| System Type | Throughput (units/hour) | Footprint (sq ft) | Features | Ideal Applications |

|---|---|---|---|---|

| Robotic Palletizer | 1000 | 30 | Flexible configuration, machine vision | Food & Beverage, Consumer Goods |

| Conventional Palletizer | 800 | 25 | High-speed operation, low maintenance | Chemicals, Pharmaceuticals |

| Hybrid Palletizer | 900 | 35 | Combines robotic and conventional features | E-commerce, Retail |

| Automated Guided Vehicle (AGV) | 700 | 40 | Self-navigating, real-time monitoring | Warehouse, Manufacturing |

| Layer Palletizer | 950 | 28 | Layer-by-layer stacking, high efficiency | Beverages, Packaging |

Related Products