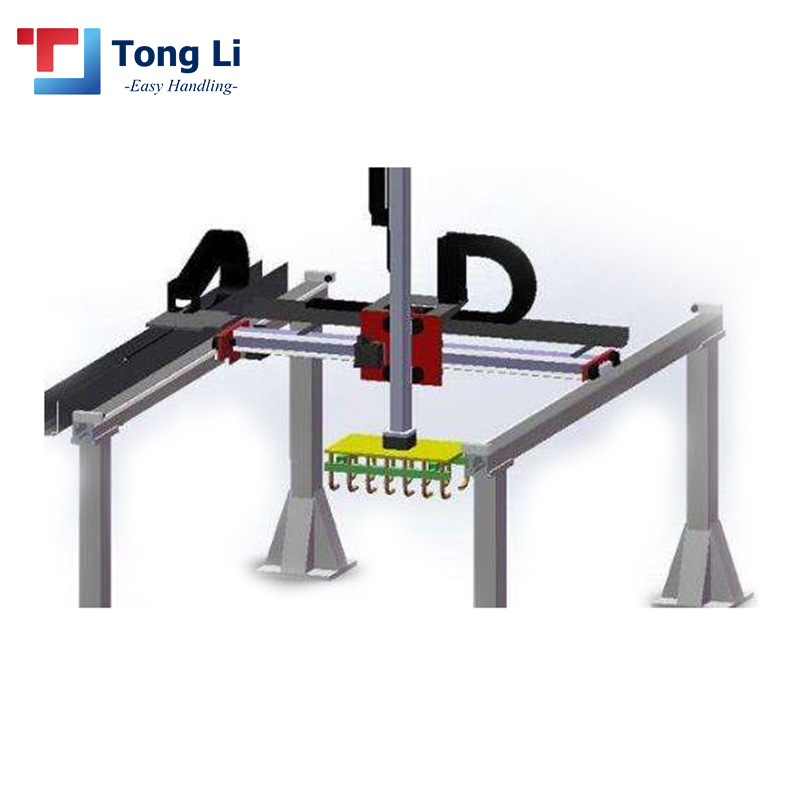

Carton palletizing robot

How It Works: The Workflow

The process typically follows a four-step cycle:

-

Infeed: Cartons arrive via a conveyor. Sensors or vision systems detect the box’s position and orientation.

-

Pick: The robot arm moves its End-of-Arm Tooling (EOAT) to the box. Depending on the design, it may pick one box at a time or a whole row/layer.

-

Place: The robot rotates and positions the box onto the pallet according to a “recipe” (a software pattern designed for stability).

-

Pallet Management: Once a pallet is full, it is moved (manually or via conveyor) to a stretch wrapper, and a new empty pallet is placed in the cell.

Key Component: End-of-Arm Tooling (EOAT)

The “hand” of the robot is the most critical part of a carton system. Common types include:

-

Vacuum Grippers: Use suction to lift boxes from the top. Ideal for sealed cartons and different sizes.

-

Clamp Grippers: Squeeze the sides of the box. Best for heavy or open-top trays where suction might fail.

-

Fork/Under-Slung Grippers: Slide tines under the box. Used for very heavy loads or unstable packaging.

Why Automate? (Top Benefits)

-

Reduced Injury Risk: Eliminates Musculoskeletal Disorders (MSDs) caused by repetitive lifting and twisting.

-

Higher Density Stacks: Robots place boxes with millimeter precision, creating more stable pallets that are less likely to tip during shipping.

-

24/7 Consistency: Unlike human operators, robots maintain the same cycle time at 3:00 AM as they do at 10:00 AM.

-

Scalability: Modern “no-code” software allows floor staff to change stacking patterns in minutes without needing a robotics engineer.