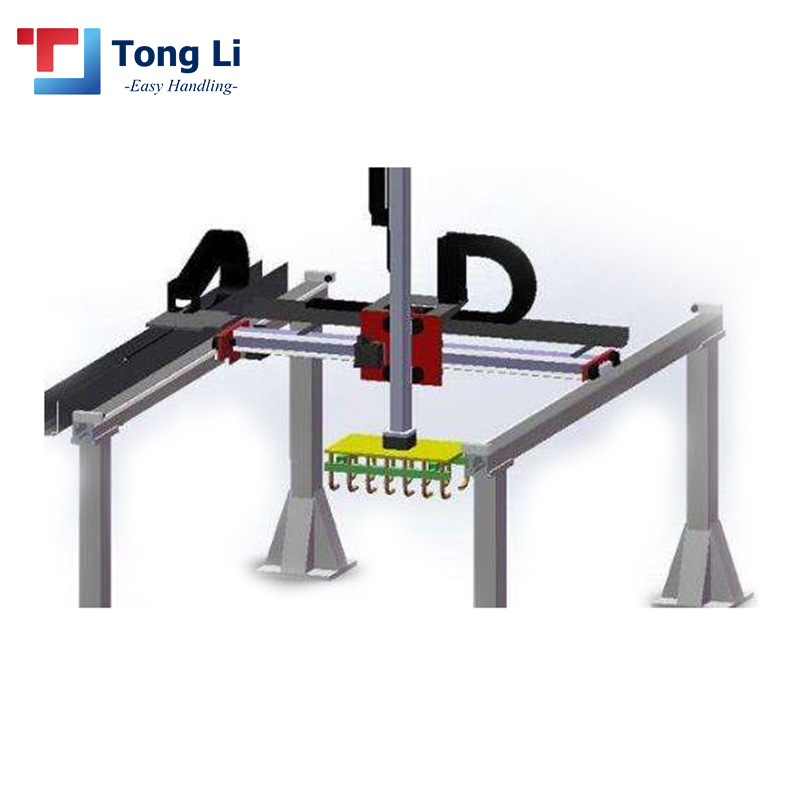

Pick and Place Gantry Robot

Core Components

-

The Bridge (Structure): An overhead frame or “gantry” that spans the work area. In a true gantry, both ends of the bridge are supported, which increases rigidity and allows for heavier payloads.

-

Linear Actuators: The drive mechanisms that provide motion. Common types include:

-

Belt Drives: High speed, ideal for long travel.

-

Ball Screws: Extremely high precision and force, but slower than belts.

-

Rack and Pinion: Best for very long distances (e.g., 30+ meters).

-

-

End Effector (The “Hand”): The tool at the end of the Z-axis that interacts with the product.

-

Vacuum Grippers: For flat surfaces like glass or boxes.

-

Mechanical Grippers: Finger-like clamps for oddly shaped parts.

-

Magnetic Grippers: For ferrous metal parts.

-

-

Control System: Usually a PLC (Programmable Logic Controller) or a dedicated motion controller that translates coordinates into motor movements.

Common Applications

-

Packaging & Palletizing: Moving boxes from a conveyor to a pallet in a specific grid pattern.

-

Machine Tending: Loading raw materials into a CNC machine and removing finished parts.

-

Electronics Assembly: High-speed placement of components on circuit boards (often called “SMT” or Surface Mount Technology).

-

Large-Scale 3D Printing/Welding: Because the frame can be built to massive sizes, they are used for building structures or welding aircraft wings.

-

Automated Storage (AS/RS): Moving bins or pallets within a warehouse shelving system.

Limitations

-

Footprint Height: Requires overhead clearance and a rigid support structure.

-

Dexterity: While they are masters of straight lines, they struggle with complex angles unless a “wrist” axis (rotational) is added to the Z-axis.

-

Obstacles: Everything within the rectangular frame must be clear; they cannot “reach around” obstacles like a jointed arm can.