Chinese wholesale Car Assembly Plant Production Line - Truss Manipulator – Tongli

Chinese wholesale Car Assembly Plant Production Line - Truss Manipulator – Tongli Detail:

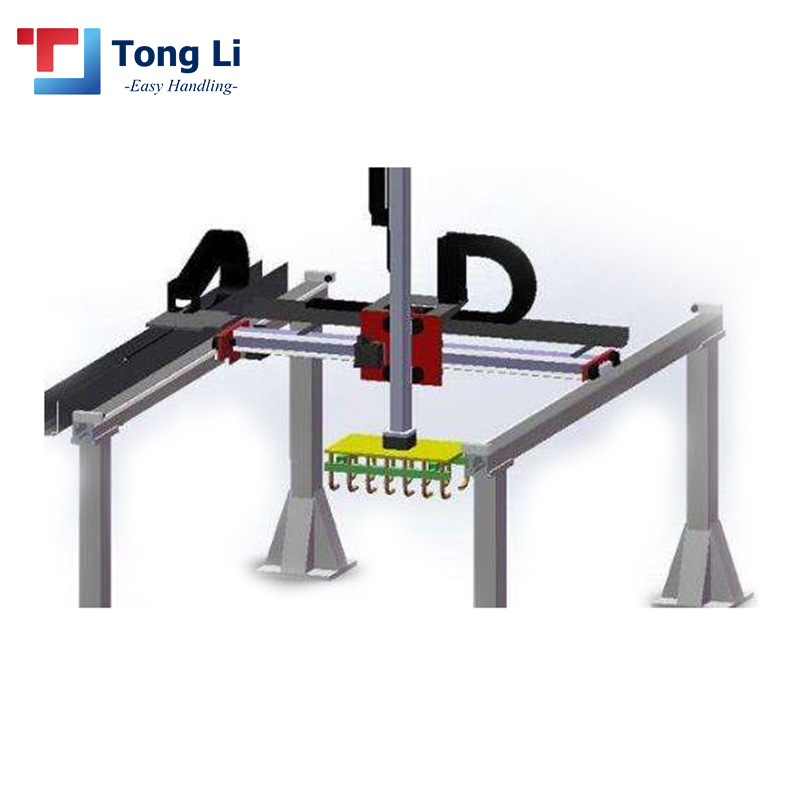

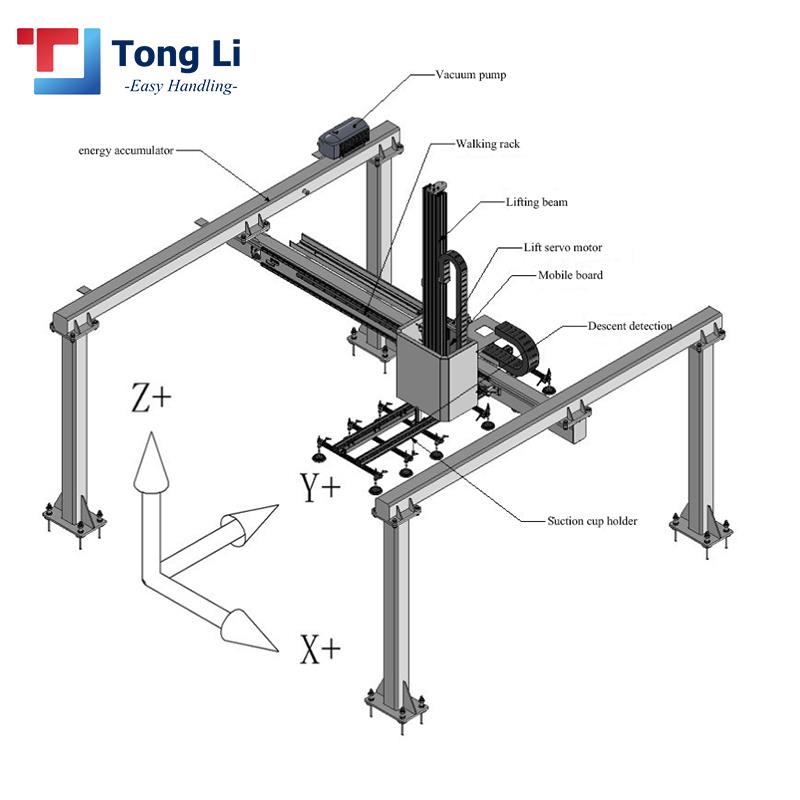

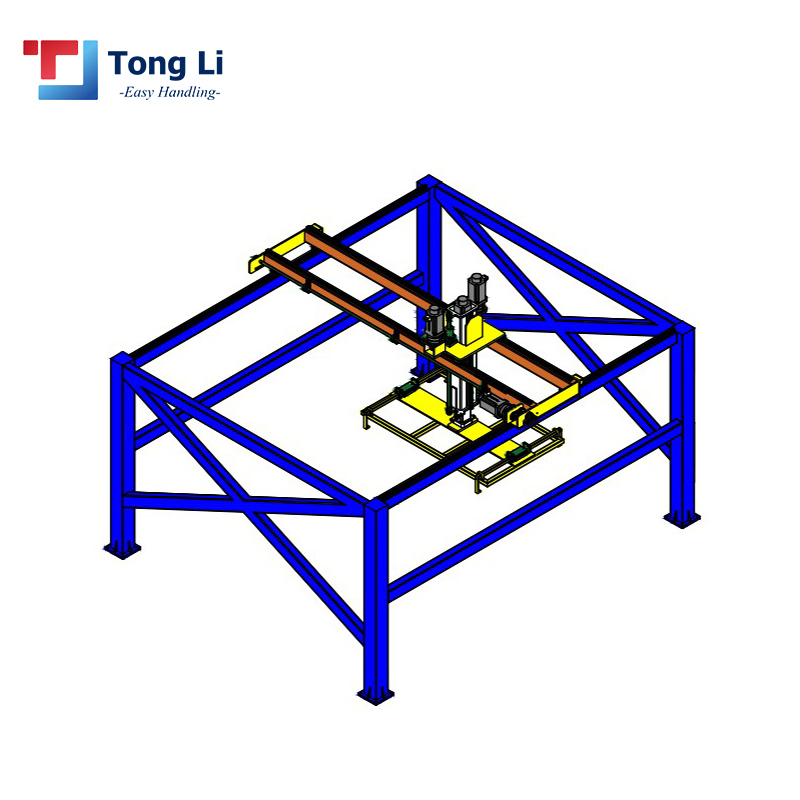

The truss manipulator uses integrated processing technology, which is suitable for loading and unloading of machine tools and production lines, workpiece turnover, workpiece rotation, etc. At the same time, its high-precision clamping and positioning tool system provides a standard interface for robot automatic processing, and repeat positioning accuracy ensures high precision , High efficiency and consistency of batch products.

The truss manipulator is a machine that can automatically stack the material which is loaded into a container (such as a carton, a woven bag, a bucket, etc.) or a packaged and unpackaged regular item. It picks up the items one by one in a certain order and arranges them on a pallet. In the process, the items can be stacked in multiple layers and pushed out, it will be convenient to go to the next step of packaging and sending to the warehouse for storage by forklift. The truss manipulator realizes intelligent operation management, which can greatly reduce the labor intensity and protect the goods well at the same time. It also has the following functions: dust prevention, moisture-proof, sun-proof, wear prevention during transportation. Therefore, it is widely used in many production enterprises such as chemical, beverage, food, beer, plastic for automatically stacking various shapes of packaging products like cartons, bags, cans, beer boxes, bottles and so on.

1. Auto parts industry

2. Food industry

3. Logistics industry

4. Processing and manufacturing

5. Tobacco and alcohol industry

6. Wood processing industry

7. Machine tool processing industry

|

Automatic truss manipulator |

|||||

|

Load(kg) |

20 |

50 |

70 |

100 |

250 |

|

Line speed |

|||||

|

X axis(m/s) |

2.3 |

1.8 |

1.6 |

1.6 |

1.5 |

|

Y axis(m/s) |

2.3 |

1.8 |

1.6 |

1.6 |

1.5 |

|

Z axis(m/s) |

1.6 |

1.3 |

1.3 |

1.1 |

1.1 |

|

Scope of work |

|||||

|

X axis(mm) |

1500-45000 |

1500-45000 |

1500-45000 |

1500-45000 |

1500-45000 |

|

Y axis(mm) |

1500-8000 |

1500-8000 |

1500-8000 |

1500-8000 |

1500-8000 |

|

Z axis(mm) |

500-2000 |

500-2000 |

500-2000 |

500-2000 |

500-2000 |

|

Repeated positioning accuracy(mm) |

±0.03 |

±0.03 |

±0.05 |

±0.05 |

±0.07 |

|

Lubrication system |

Concentrated or independent lubrication |

Concentrated or independent lubrication |

Concentrated or independent lubrication |

Concentrated or independent lubrication |

Concentrated or independent lubrication |

|

Accelerated speed(㎡/s) |

3 |

3 |

3 |

2.5 |

2 |

Product detail pictures:

Related Product Guide:

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme for Chinese wholesale Car Assembly Plant Production Line - Truss Manipulator – Tongli , The product will supply to all over the world, such as: UK, UK, New Zealand, Our mission is to deliver consistently superior value to our customers and their clients. This commitment permeates everything we do, driving us to continuously develop and improve our products and the processes to fulfill your needs.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.