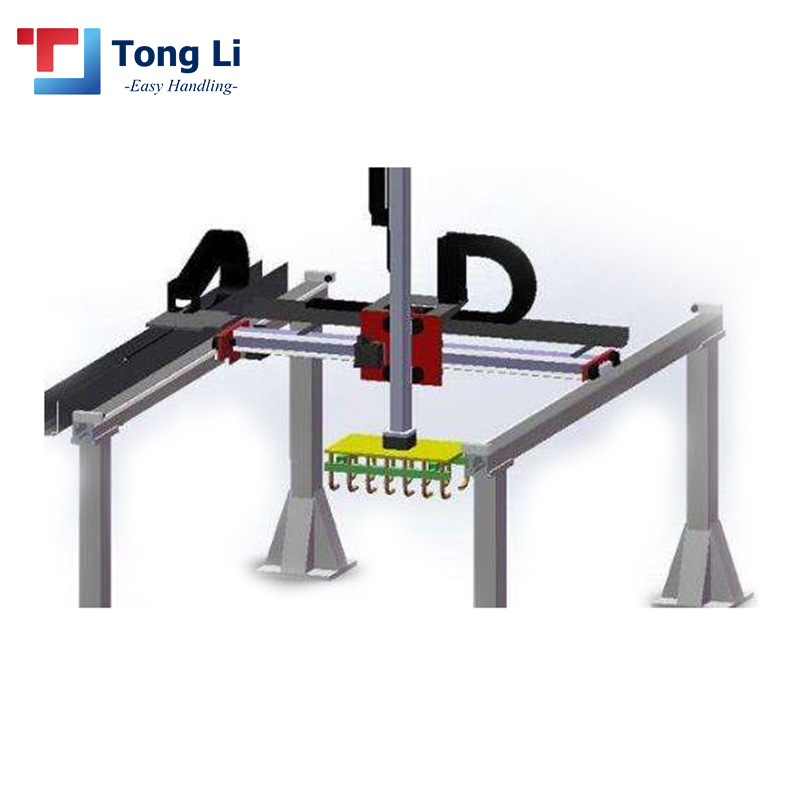

Chinese wholesale Car Assembly Plant Production Line - Multiaxial Manipulator – Tongli

Chinese wholesale Car Assembly Plant Production Line - Multiaxial Manipulator – Tongli Detail:

1. Freedom movement; 2. Automatic control and repeatable programming; 3. Flexible with different functions according to different operating tools; 4. High reliability, high speed, high precision.

As a low-cost and simple system structure for automated robot system solutions, multi-axis manipulators can be used in dispensing, plastic dropping, spraying, palletizing, sorting, packaging, welding, metal processing, handling, loading and unloading, assembly common industrial production fields such as, printing, etc., have significant application value in terms of replacing labor, improving production efficiency, and stabilizing product quality. For different applications, there are different design requirements for multi-axis manipulators, such as selecting different transmission methods according to the requirements of accuracy and speed, and selecting different clamping devices (fixtures, grippers, and mounting frame, etc) for the end working head according to specific process requirements,as well as design options for teaching programming, coordinate positioning, visual recognition and other working modes, so that it can meet the application requirements of different fields and different working conditions.

The multi-axis robot is a general-purpose robot with compact appearance and structure. Each joint is equipped with a high-precision reducer. The high-speed joint speed can perform flexible operations. It can perform operations such as handling, palletizing, assembly, and injection molding. Installation method.

(1) Material handling and palletizing (2) Packaging and assembly (3) Grinding and polishing (4) Laser welding (5) Spot welding (6) Injection molding (7) Cutting/deburring

●Adopt the structure of servo motor and reducer, with strong carrying capacity, large working range, fast speed and high precision.

●The control system manipulator is simple and easy to learn, which is very suitable for production use.

●The robot body adopts partial internal wiring, which is safe and environmentally friendly.

Product detail pictures:

Related Product Guide:

Our products and solutions are greatly recognized and trustworthy by customers and may fulfill constantly changing financial and social requires for Chinese wholesale Car Assembly Plant Production Line - Multiaxial Manipulator – Tongli , The product will supply to all over the world, such as: Argentina, Czech republic, Hungary, Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part products. Our advantage is full category, high quality and competitive price! Based on that, our products win a high admiration both at home and abroad.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!